Related Topic

Cleaning and Disinfection Program for Breeder Flocks ( with disinfectant's doses)

Best Practices for Cleaning download pdf here

The Chicken House

Overview

General overview of

C&D

·

Detailed review

·

Darkling beetle infestation

·

Rodent infestation

·

Water, a source of

infection

The Objective

To clean and disinfect

the poultry house so that all potential poultry and human pathogens are removed

and to minimize the numbers of residual bacteria, viruses, parasites and

insects etc. between flocks minimizing any effect on health, welfare and

performance of the subsequent flock.

Clean out Stages

1. Planning 2. Depletion

3. Insecticide application 4. Rodent control

5. Remove

dust 6. Pre-soak

7. Remove

equipment 8. Remove

litter – litter disposal

9. Cleaning of water lines 10. Reapply

insecticide

11. Sweep 12. Washing

13. Drying 14.

Disinfection

15. Reapply insecticide 16.

Fumigation

17. Rodent control

Planning

Depletion

“Simply culling of breeders flock after the age of 64

weeks “

Darkling Beetles and Disease

• IBDV, MDV • NDV and

AIV

• Reo

viruses, ILT, Fowl Pox • Salmonella

• Campylobacter • E. coli

• Aspergillus, Staphylococcus • Coccidia

• Roundworms • Fowl

tapeworm

Facts Facts

• Average

beetle size (≈6mm long, 100mg)

· Assuming

beetles convert feed as well as

broilers; bug load could cost 1 point of FCR

• In a

complex killing 1 million birds/week, 1 point of FCR can cost up to an estimated $300,000/year

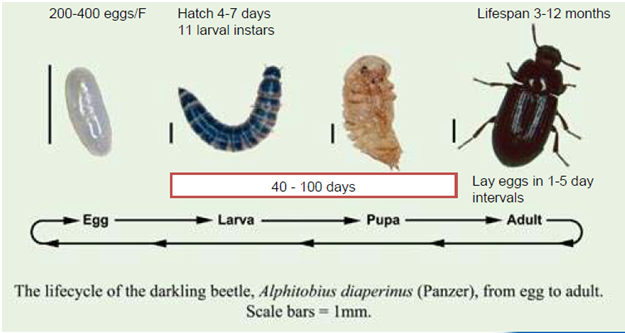

Life Cycle

|

| Life cycle of darkling beetles |

Effective darkling beetle control program

• Identify

darkling beetle infestation

• Keep

litter moisture low (key nutrient for

larvae and beetles).

• Regular

maintenance of water lines will prevent leaking and will help reduce beetle numbers.

• Use a

pesticide that is suitable for the type and location of treatment.

Follow label instructions

for application procedures and rates.

• Rotate

insecticides and the use of boric acid.

• Treat

within 24 to 48* hours after birds are removed from the house.

• Apply

treatments in a manner that can reach beetles and larvae that may be several inches under the litter. Use the highest permitted rate.

application and only mix it within a 2 to 3 inch depth.

Alphitobius diaperinus

|

Controlling Alphitobius diaperinus

In Broiler Houses

• Trials

were conducted during one year under field conditions

• Tested

combined treatment

— Adulticide

– cyfluthrin [sī-floo-thrǐn]

— Larvicide

- triflumuron [trī-floo-mūrǒn]

• The

combined insecticide treatment greatly reduced the adult and larval stocks throughout

the different broiler growing periods, and control of A. diaperinus populations was achieved by the end of the

second

Darkling Beetles Eat Feed

·

There can

be up to 2 million darkling beetles and larvae in a broiler house

·

Average

beetle size (≈6 mm long, 100 mg) and assuming beetles convert feed as well as

broilers; bug load could cost 1 point of FCR

·

In a

complex killing 1 million birds/week, 1 point of FCR can cost up to an

estimated $300,000/year

Rodent Control

Estimating Rat Populations

• Rule of thumb:

—If you don’t see rats but see signs of them, there are ~1 to

100

—If you see them occasionally at night, there are ~100 to 500

—Occasional daytime and numerous night sightings indicate ~400

to 1,000

—Seeing several in the daytime may indicate a presence of as

many as 5,000.

Fill Gapes

Cats and Dogs Can Carry

Pathogens

• Physical vector

• Pasteurella• Salmonella

• Others…H5N1• Swine dysentery (Brachyspira ssp.)

Pre Spray

• Sprayer

or low pressure washer

• Ceiling

to floor

• Dampen down

dust

Remove Equipment

• Frames/Nest Boxes

• Supplementary

Equipment

• If it can’t be wet

Cleaned or removed-

Dry clean and cover it up!

• Environmental sensors etc!

Remove Litter

• Remove

all litter and debris

• Final dry

brush of floor

• Avoid

windy weather

• Use

covered trailers

• Disinfect wheels

Litter Disposal

• > 2 km

from the farm

• Method of

disposal

— Spread

and ploughed in arable land

— Landfill

— Composting

— Incinerating

• Follow

government regulations

— Traceability

— Nitrites

— Nitrates

Washing

Internally and Externally

• Pressure

washers-

100 bar min

• Preferably

hot water > 40oC

• Suitable

Chemicals

• Interactions

• Aluminum

houses- Foam Detergent

• Wood-Traditional

Detergent

• Correct

Dilution rates

• The

correct sequence

Dilution Ratio Table

Water in liters

|

0.5

|

1

|

2

|

5

|

10

|

Dilution ratio

|

|||||

Dilution Ratio

|

|||||

1:20

|

25ml

|

50ml

|

100ml

|

250ml

|

500ml

|

1:40

|

13ml

|

25ml

|

50ml

|

125ml

|

250ml

|

1:50

|

10ml

|

20ml

|

40ml

|

100ml

|

200ml

|

1:60

|

8ml

|

16ml

|

33ml

|

83ml

|

166ml

|

1:80

|

6ml

|

13ml

|

25ml

|

63ml

|

125ml

|

1:100

|

5ml

|

10ml

|

20ml

|

50ml

|

100ml

|

1:150

|

3ml

|

7ml

|

13ml

|

33ml

|

67ml

|

1:200

|

3ml

|

5ml

|

10ml

|

25ml

|

50ml

|

Sequence

- From apex to downwards

- Start at the rear of the house and move to the front

- Pay attention to cracks and joints

Washing Stages

• Detergent

• Rinse

• Excess

water collected

• Visual

Check

Poultry Water Line Cleaning:

Overrated or Underappreciated?

“The evidence is growing that water

sanitation can be a crucial tool in addressing

poor poultry flock performance”

When the poultry

industry advanced from open drinkers and troughs to enclosed nipple lines, it

was the perfect solution to both labor and contamination challenges. Yet the

test of times has proven that while enclosing water supply in a poultry barns

has greatly improved water sanitary qualities, it has not eliminate the risk of

disease challenges.

Bio film Slime

• Poor line

sanitation _ bio film

• Bio film

lives on very little nutrients

• Can cause

health challenges, flock after flock

• Disease

agents like E. coli and Salmonella

— Salmonella may be

isolated from 7 to 8% of water samples collected from nipple drinker systems.

• Once

established is 10-1000x harder to remove

• Can

return in 2-3 days after cleaning

— When we

do a poor job of cleaning

— When we

don’t keep water sanitized

— When we

add food supply

What Influences Bio-films?

• Natural

contaminants Iron, manganese,

sulfur

• Vitamins • Electrolytes • Organic

acids

• Sugar

water • Vaccines

and vaccine stabilizers

• Probiotics

and Antibiotics • Do you

clean lines after product use?

• How often

is water sanitation?

sacrificed so water can be delivery route for products?

Water System

• Drain pipes and

tanks • Flush

lines

• Cleanse

header tanks • Scale /

bio film removal

• Refill

tanks and add sanitizer • After

4-24hrs remove solution

• Rinse with

fresh water

• Run sanitizer solution through lines (check no air locks)

Feed System

• Ensure bulk bins and augers are free of feed

• Dry brush

• Do not introduce water to the bulk bins!!

• Wash and disinfect pans, tracks, auger pipes etc

Repairs and Maintenance

• Prior to

final disinfection

• Gas and

electrics

• Buildings

and Equipment

• Concrete

Repairs

• Vermin

proofing

• Wild bird

proofing

• Clear

Drains

Disinfection

• Only when

buildings are internally and externally clean

• Repairs

are complete

• No

organic matter

• Correct dilution

rates

• Remember

the sequence

Fumigation Monitoring Effectiveness

• Damp

Surface (not puddles) • TVC’s

Total Viable Counts

• Seal

house tight • Salmonella

• Warm

house to 21oC (70RH) • Set

Standards

• Seal gas

in house for 24 hrs • Monitor

Trends

Summary

• Adopt,

develop standard operating procedures

• Clean and

disinfect after every flock

• Monitor

effectiveness

• Darkling

beetles and rodents are potential sources of Salmonella, etc.

• Water is

often neglected

• Allow

adequate down time between

Related Topic

Cleaning and Disinfection Program for Breeder Flocks ( with disinfectant's doses)

4 comments:

I know your expertise on this. I must say we should have an online discussion on this. Writing only comments will close the discussion straight away! And will restrict the benefits from this information.

הרחקת יונים

This article is very interesting and helpful. Thank you for sharing! If you have any difficulties in cleaning difficult dirt, you can use water blaster. Water blaster can help you clean anything faster and easier.

I wanted to thank you for this excellent read!! I definitely loved every little bit of it. I have you bookmarked your site to check out the new stuff you post Vivo Y15 Price In Pakistan

Really thanks to everyone one

Post a Comment